During the first months of the project, the consortium partners kicked-off the research in four European regions, called Food Circles. What have they been up to? Read a short overview below.

Food Circle 1 develops a mobile fruit processing unit for low oxygen juice extraction and mild preservation. A 3D model of the unit is drafted. A self-lifting system was chosen to be the most adequate mobility system. The operating system and the design of the production line will depend on the capacity range and scaling down the ability of the processing machines.

Lake Constance region in Germany

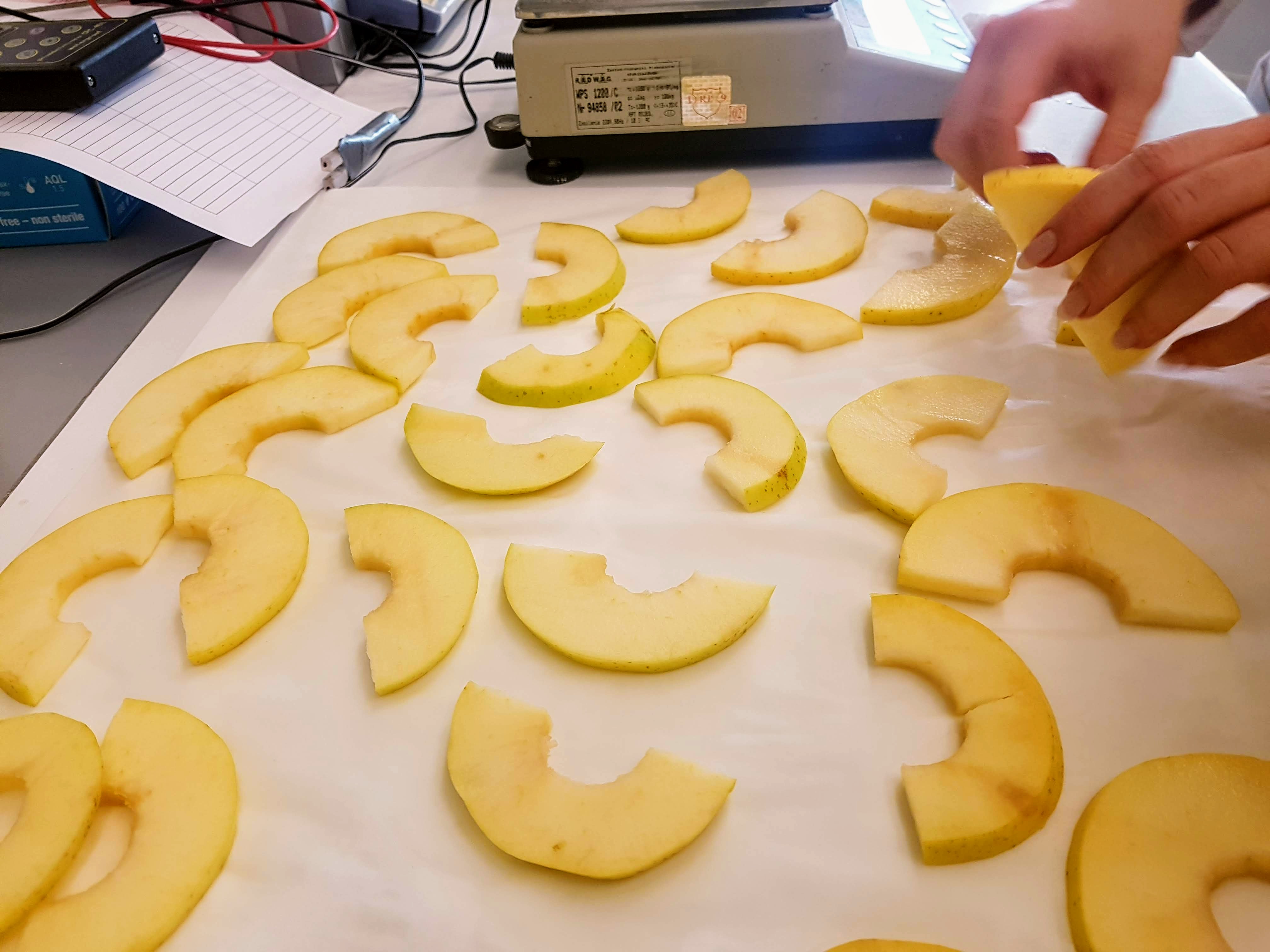

Food Circle 2 has examined the efficiency of three different methods of pre-treatment before drying: ultrasounds, high-pressure processing and pulsed electric field (PEF). The PEF treatment appeared to be the most promising technology suitable for low-temperature drying of fruits, vegetables and mushrooms for development of healthy and sustainable snacks.

Central Bohemian Region in the Czech Republic & Kuyavian-Pomeranian Voivodeship region in Poland

Food Circle 3 defines the 4 target products and their specific packaging systems. Ready-to-eat fresh-cut fruit and vegetable snacks will be packaged in recyclable PET. Ready-to-eat fresh-cut fruit and vegetable pieces for a smoothie will be packaged in compostable and biobased PLA material.

Valencia, Spain and Alpes Côte d’Azur, France

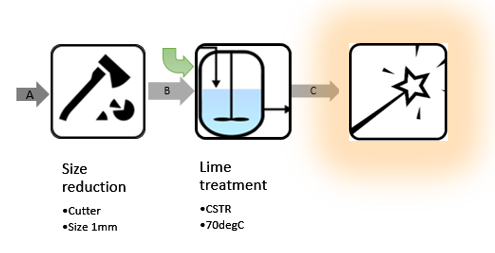

Food Circle 4 makes smart choices with the process selection tool that is under development within the upcycling of plant-based food side streams by using mild processing. The flexible modular set-up is designed to handle a different kind of side streams and different processing options are tackled with process wizards.

Noord-Brabant, the Netherlands

![FOX at FI [Food Ingredients] Europe](https://www.fox-foodprocessinginabox.eu/wp-content/uploads/2022/12/Screenshot-2022-12-13-131707.png)