Food Circle 1: Low oxygen juice extraction and mild preservation

The aim

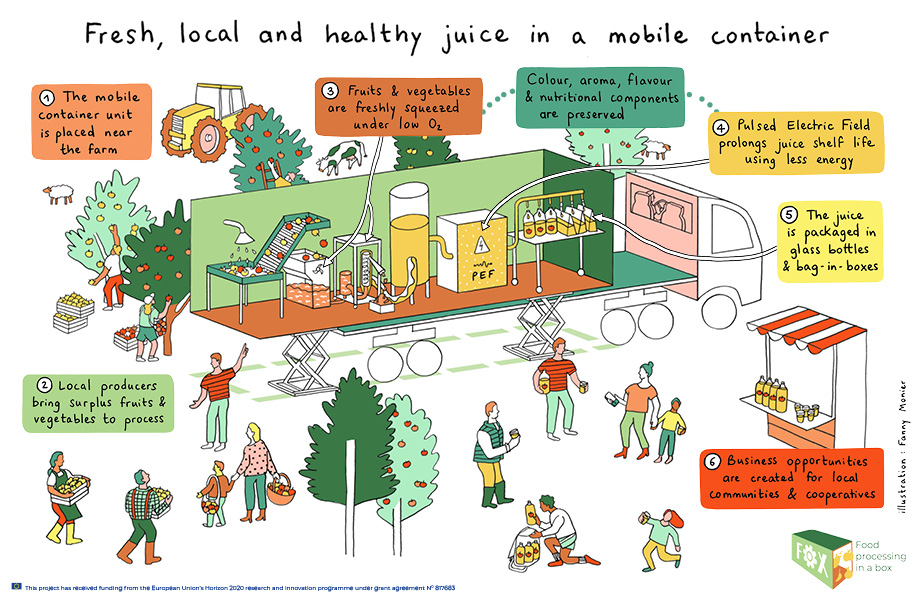

Food Circle 1 aims to develop small-scale mobile processing unit, that will enable:

- High-quality fruit juices and puree production

- Flexible production for different types of fruits

- Practical and simple installation and operation on the farm(s)

During the harvest period, the mobile processing unit at the farm should process a peak amount of fruits without quality loss. High-quality fruit/puree production should be achieved with downscaled, innovative technologies for low oxygen juice/puree extraction and low heat preservation.

Juice production

The main processing steps in juice production are:

- Sorting

- Washing

- Crushing

- Juice extraction

- Juice preservation

- Juice Filling

These processing steps are mostly done on a large industrial scale. The challenge lays in downscaling these processes, meaning fitting them into a single processing line to match the mobile unit size. Researchers main focus will be on down-scaling and implementation of innovative extraction and preservation technologies.

Technologies used

- Spiral filter press

Spiral filter press is used for gentle low oxygen juice and puree preparation under vacuum conditions. This technology minimises the contact of freshly pressed product and air which results in more intense and more authentic colour, aroma and flavour. Furthermore, juice/puree processed this way has better consistency (viscosity) and richer nutritional composition, resulting in overall better sensorial and nutritional characteristics. This system provides better extraction and preservation of valuable compounds (no oxidation) in juice, compared to more traditional methods commonly being used.

The innovative mild preservation technology used is called Pulsed Electric Field (PEF) technology. PEF enables inactivation of spoilage and pathogenic microorganisms in liquid products, such as juices, purees, smoothies, milk, etc while minimally influencing (affecting) its fresh character. The advantages of PEF technique compared to classical heat pasteurization are lower energy consumption (it is more sustainable), higher efficiency (treatment lasts few milliseconds) and due to low heat treatment preservation of original colour, flavour and nutritional composition of juices/purees.

PEF (Pulsed Electric Field) technology is relatively new but already used by the juice industry in several countries. Project partners DIL and ELEA have successfully developed and realised PEF systems for low heat PEF preservation of liquids up to 10.000 l/h. The obtained knowledge and experience will be used for the design and building of a small-scale PEF unit with capacity range from 50 to 250 L/h, suitable for on-farm use.

There is no need for the addition of preservatives, colourants or aromas when combining these two techniques. The final product is all-natural.

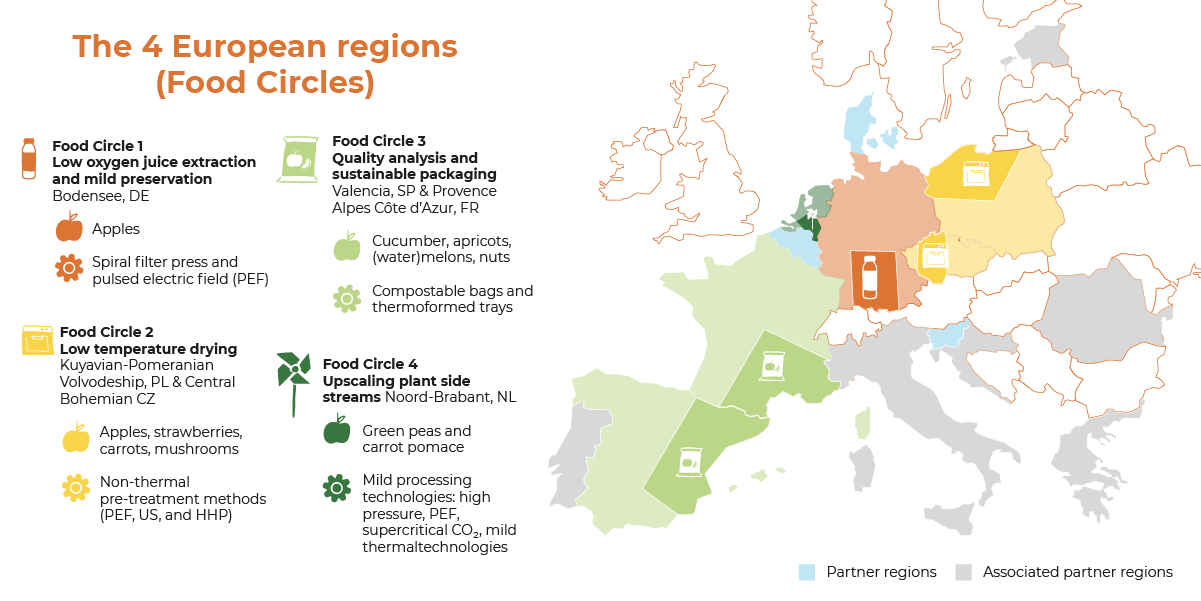

The region

Prototypes of small-scale juice production units will be tested for feasibility and practicability at farms in the Lake Constance (Bodensee) region in Germany.

Project partners

The project partners involved in Food Circle 1 are DIL e.V, ELEA GmbH, KOB e.V and FALKENSTEIN GmbH.

Food Circle 1 News

14th International Conference on Agrophysics

14th International Conference on Agrophysics The 14th International Conference [...]

DIL Technology Day 2023 Showcases Cutting-Edge Solutions for the Food Industry

DIL Technology Day 2023: Discover Exciting Food Industry Innovations [...]

Tagus Valley invites FOX for PEF Workshop

On LinkedIn Visit the website tagusvalley.pt [...]

6th Edition FOX Newsletter – Out now!

The FOX team is ready for the final year [...]

FOX at the PROTECT/TRANSIT Symposium

FOX partner and head of advanced technologies at DIL, [...]

FOX Segment Meeting in the Bodensee region, Germany

On Tuesday the 4th and Wednesday the 5th of [...]

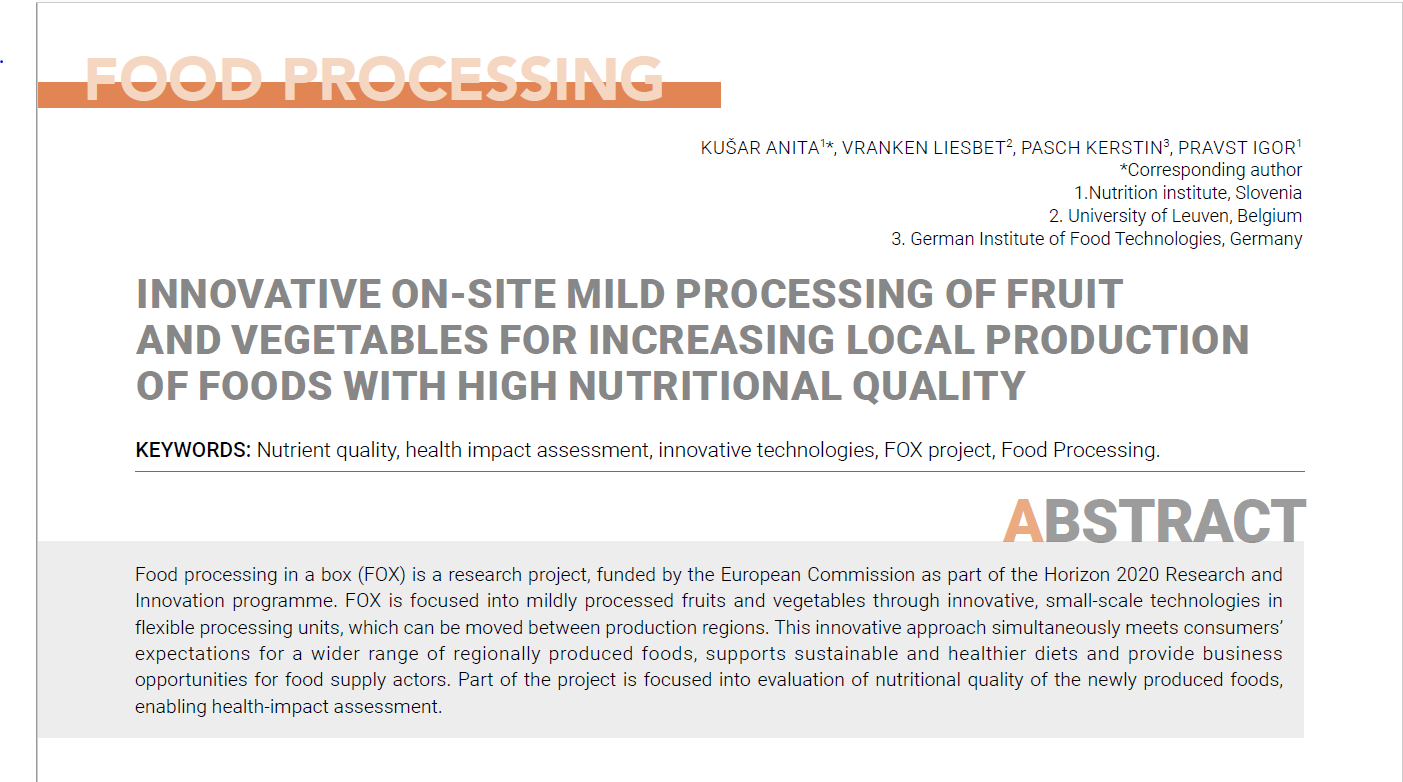

NUTRIS publishes in Agro FOOD Industry Hi-Tech Journal

Anita Kušar, from our partner the Nutrition Institute, has published a paper [...]

FOX Animated video: Innovative local fruit and vegetable processing units

Now out: The FOX animated video "Innovative local fruit and [...]

The FOX container arriving to KOB (Germany)

On the 16th May, the first FOX container, a mobile [...]

FOX Annual Meeting in Warsaw at SGGW

FOX partners met on the 27th and 28th June [...]

FOX – Food in a Box attending “The Food Club”

Björn Moller from the FOX partner, Fraunhofer, was invited to [...]

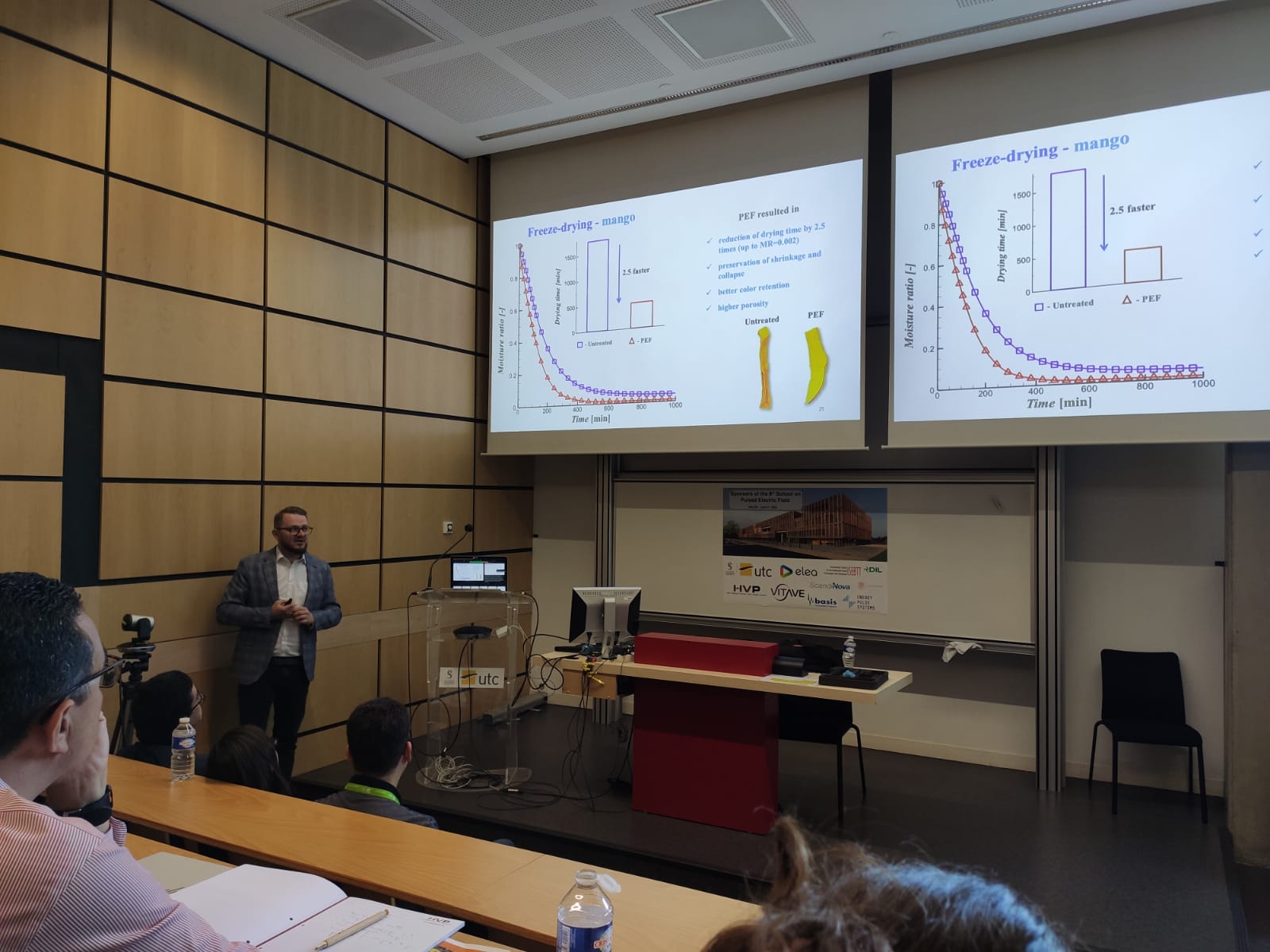

FOX was in PEF School?

Two FOX partners participated in the 8th PEF School that [...]

Infographics: FOX Food Circles Explained

The FOX project works within four areas of innovation, [...]

FOX as an example of Sustainable and Circular Food Production

On the 8th of June, Dr. Artur Wiktor, Assistant Professor [...]

FOX was on the TV, did you miss it?

On the 19th of May of 2022, the German regio [...]

ELEA in AnugaFoodTec 2022

FOX partner, ELEA in the AnugaFoodTec 2022. Anuga FoodTec took [...]

Elea and EnWave Event

Elea and EnWave provided insights and demonstrations of the Synergizing [...]

PEF (Pulsed Electric Field) Technology

FOX (Food in a box) aims to rethink the [...]

FOX and ZeroW EU Project

The European project ZeroW (Systemic Innovations Towards a Zero [...]

Launch of the first FOX container

Producing the first apple juice using the FOX container. [...]